|||||||||||| XH MAR BETHLEHEM

BOILERS

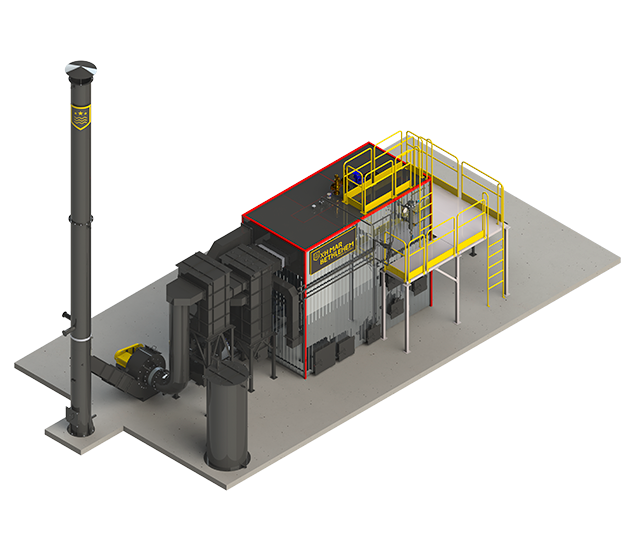

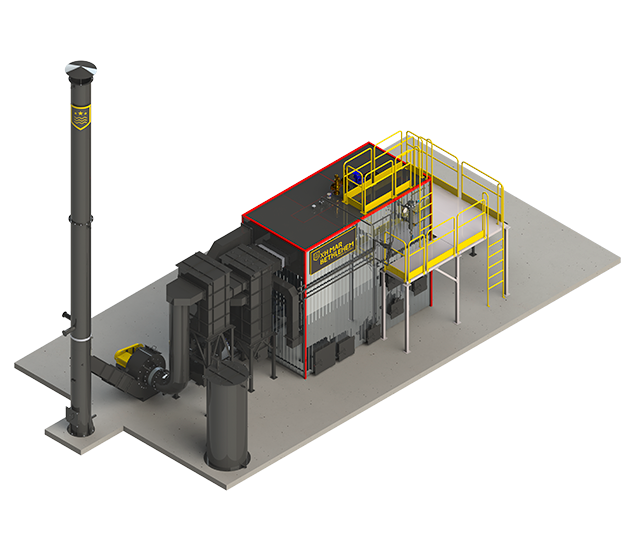

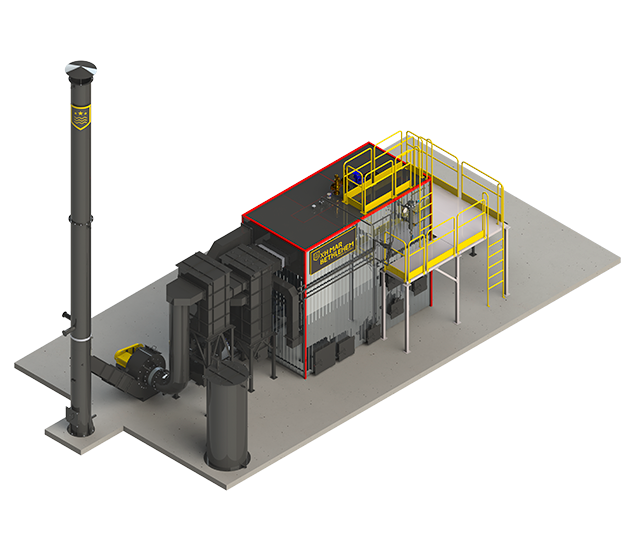

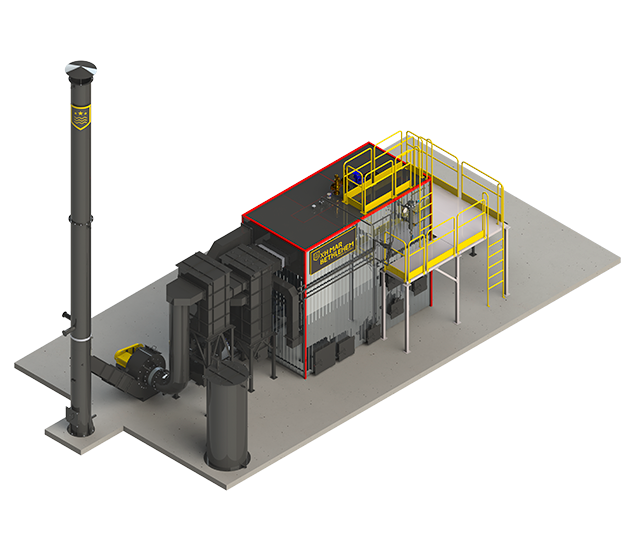

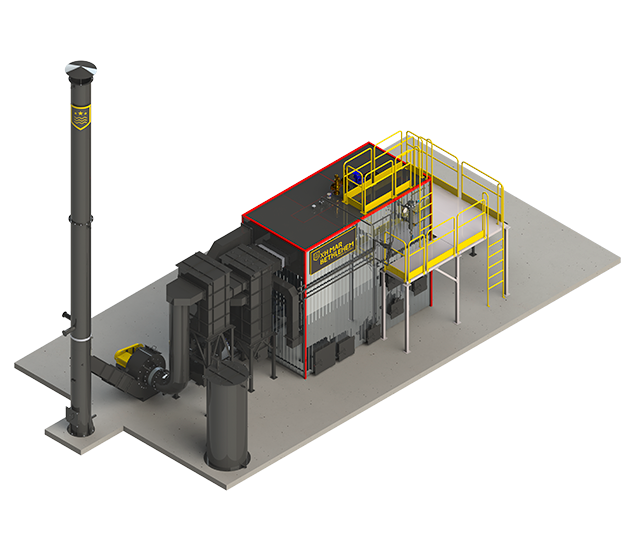

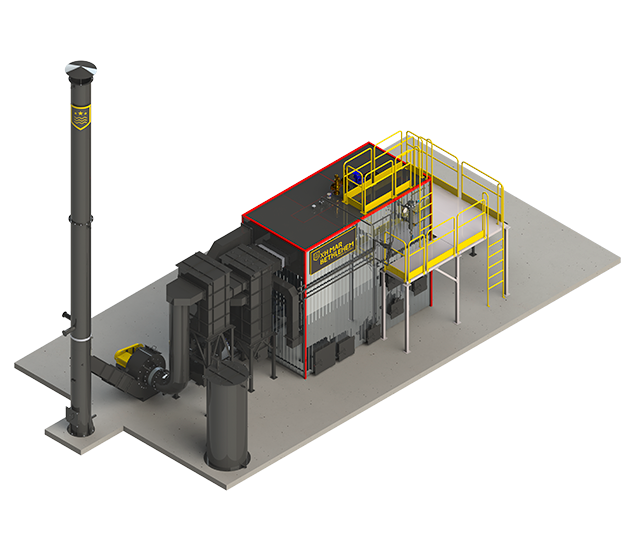

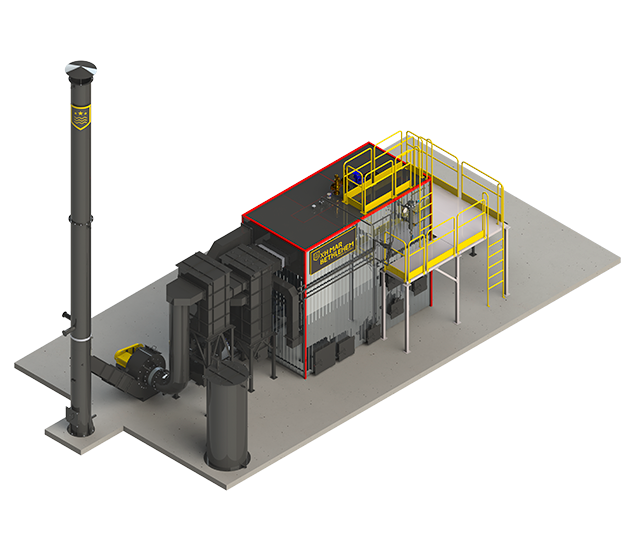

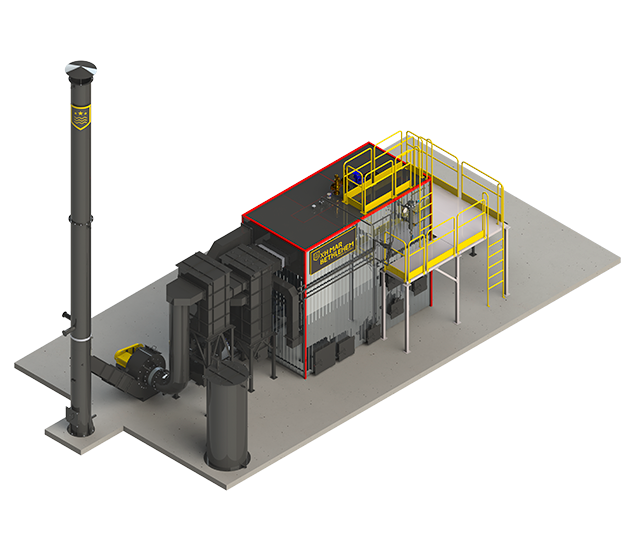

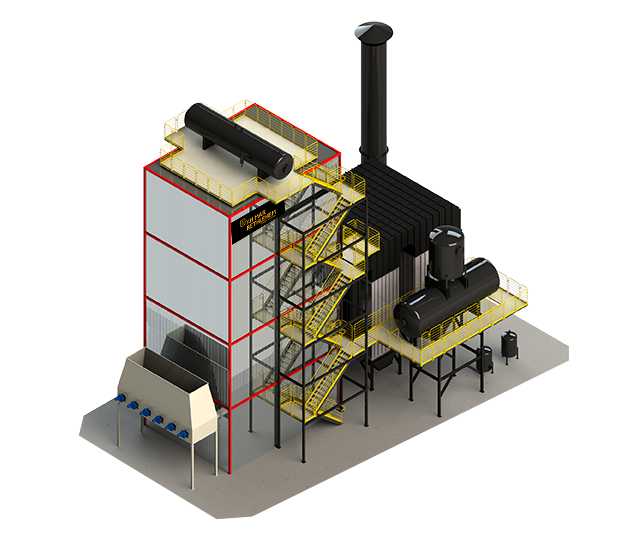

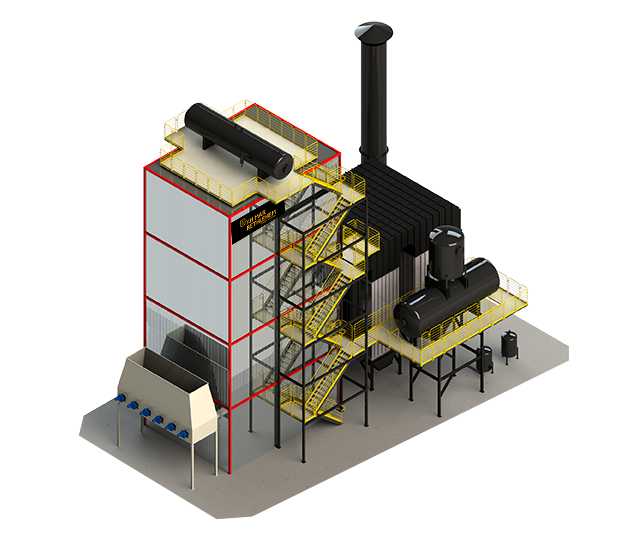

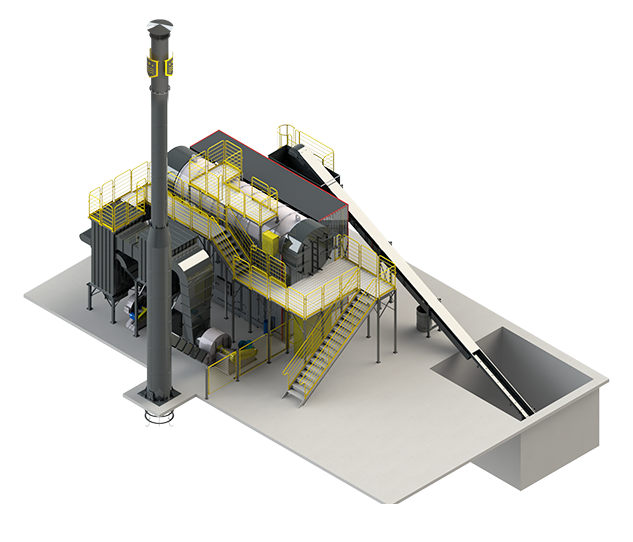

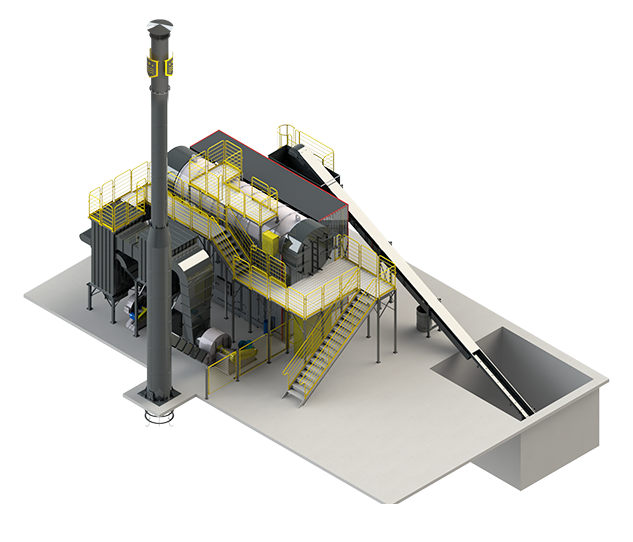

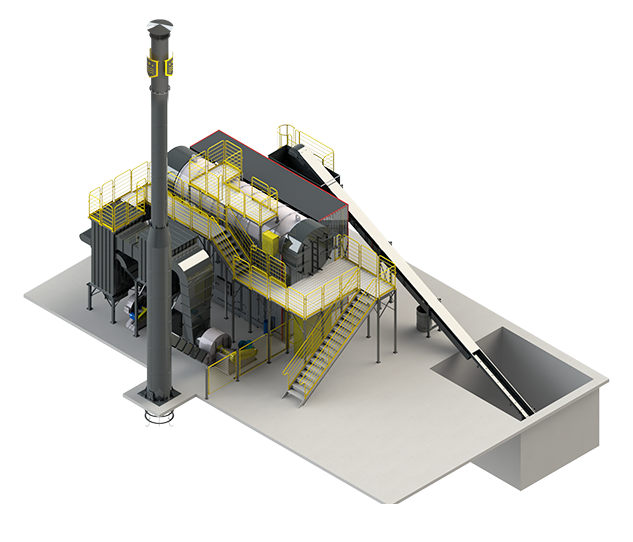

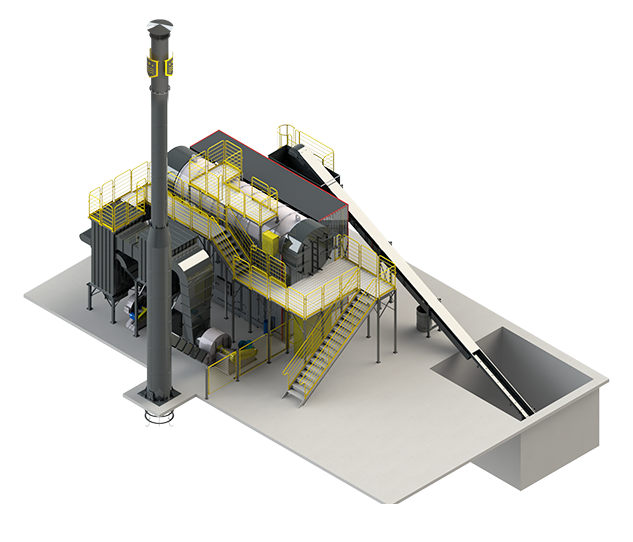

Due to a competitive market, XH MAR BETHLEHEM has developed its own boilers for the industry, presenting a complete idea for boilers, with the models Water Tube, Fire Tube and Hybrid.

The XH MAR BETHLEHEM boilers projects arised from the constant need for improvement and evolution of the product. The boilers are characterized by a modern conception project, endowed with a large combustion chamber, with no purging of unburnt particles, and with distinguished grates, namely the models Cota Zero and Drilled, presenting the greatest burning efficiency among existing technologies.

|||||||||||| XH MAR BETHLEHEM

CALDEIRAS

Na razão de um mercado competitivo, a XH MAR BETHLEHEN desenvolveu suas próprias caldeiras para a indústria, apresentando uma ideia completa para caldeiras, no modelo aquatubular, flamotubular e mista.

Os projetos de caldeiras da XH MAR BETHLEHEM surgiram a partir da constante busca por melhorias e evolução do produto, e se caracterizam por um projeto de concepção moderna, dotada de uma ampla câmara de combustão, sem o arraste de particulado não queimado e possuem diferenciadas grelhas, tipo Cota Zero e Drilled com maior eficiência de queima das tecnologias já existentes.

BOILERS

Due to a competitive market, XH MAR BETHLEHEM has developed its own boilers for the industry, presenting a complete idea for boilers, with the models Water Tube, Fire Tube and Hybrid.

The XH MAR BETHLEHEM boilers projects arised from the constant need for improvement and evolution of the product. The boilers are characterized by a modern conception project, endowed with a large combustion chamber, with no purging of unburnt particles, and with distinguished grates, namely the models Cota Zero and Drilled, presenting the greatest burning efficiency among existing technologies.

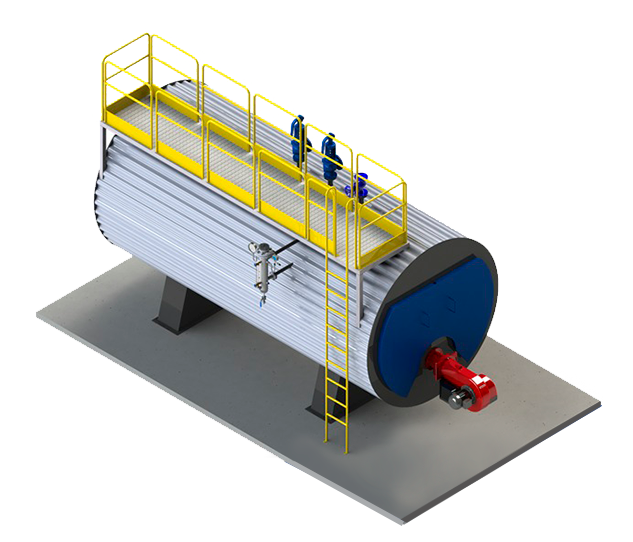

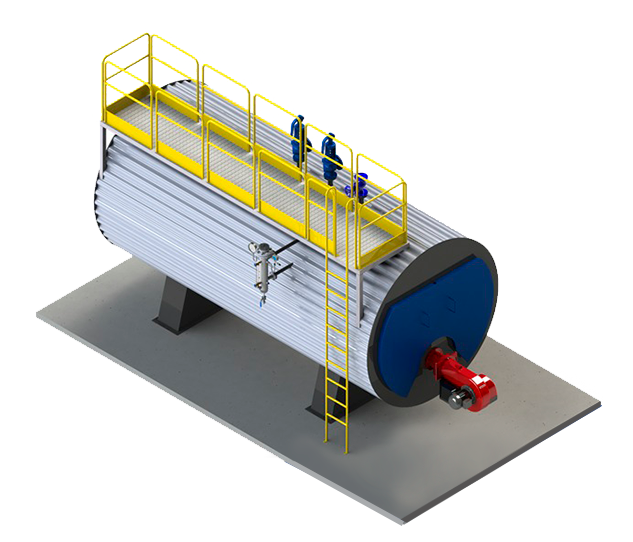

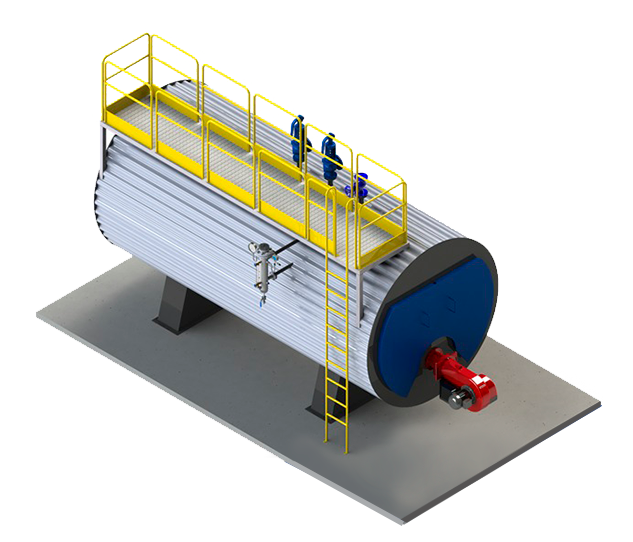

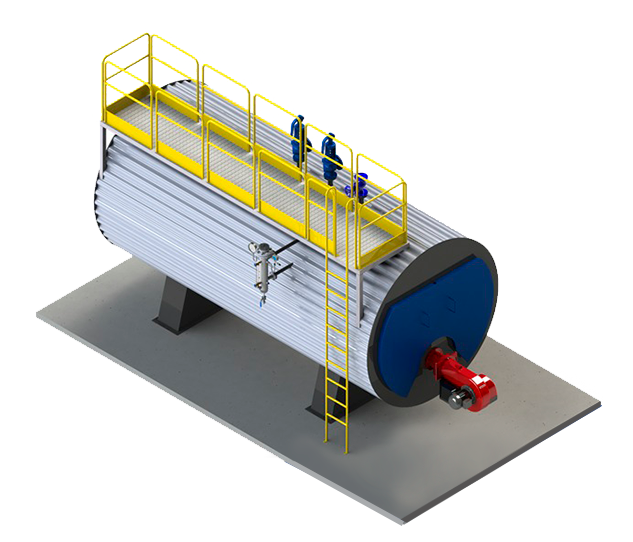

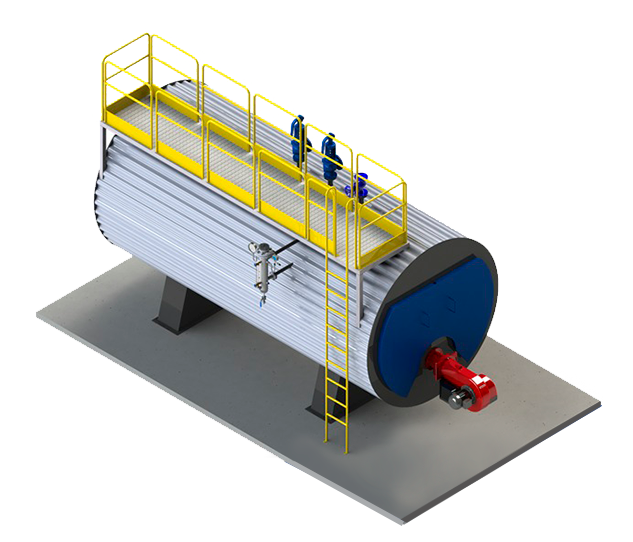

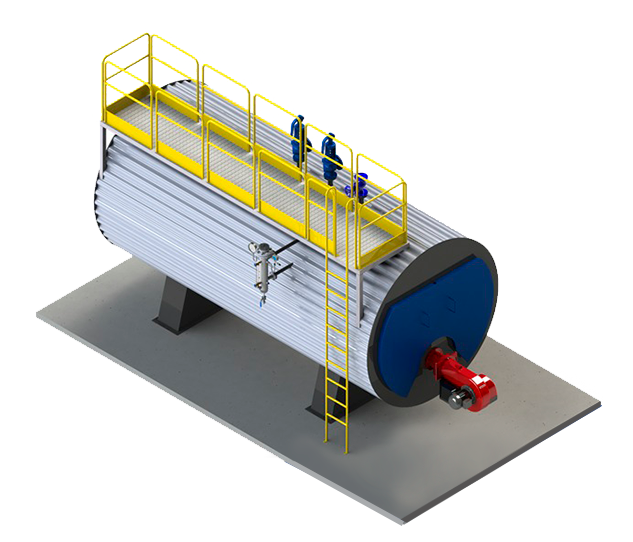

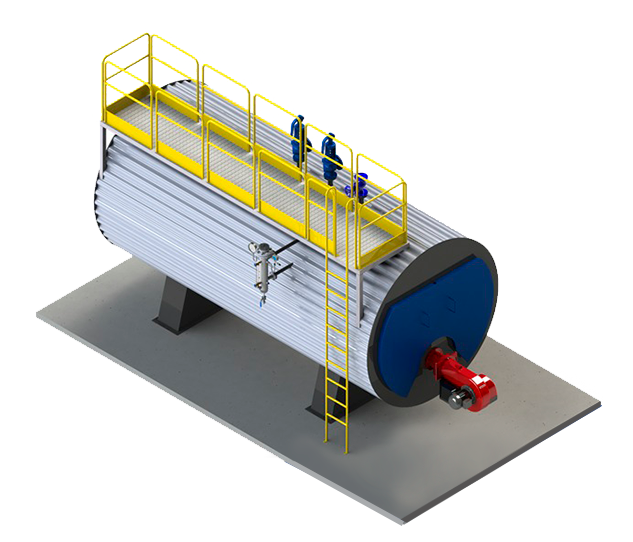

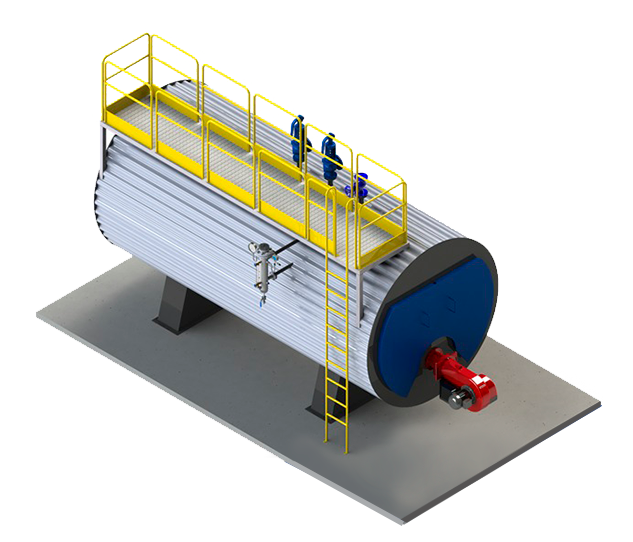

FIRE TUBE BOILER

Fire tube boilers are so called because of the way their combustion process is carried out: the combustion gases circulate inside their flame tubes of the steam generator, and around them the water that will be heated.

They can have small dimensions, facilitating their use, and they work through liquid fuels, such as fuel oil and gas (natural and LPG).

CALDEIRA FLAMOTUBULAR

As caldeiras flamotubulares são assim chamadas devido a forma como é realizado seu processo de combustão: dentro de seus tubos de chama do gerador de vapor, circulam os gases da combustão e em seu entorno a água que será aquecida.

Elas podem possuir pequenas dimensões, facilitando seu uso, e funcionam através de combustíveis líquidos, como o óleo BPF e gás (natural e GLP).

FIRE TUBE BOILER

Fire tube boilers are so called because of the way their combustion process is carried out: the combustion gases circulate inside their flame tubes of the steam generator, and around them the water that will be heated.

They can have small dimensions, facilitating their use, and they work through liquid fuels, such as fuel oil and gas (natural and LPG).

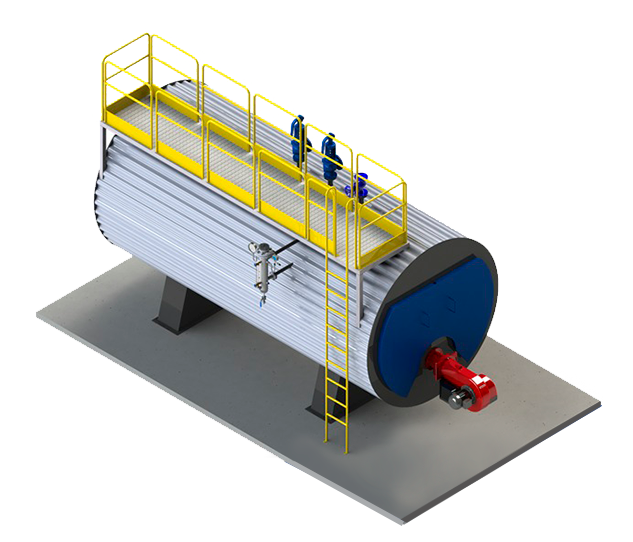

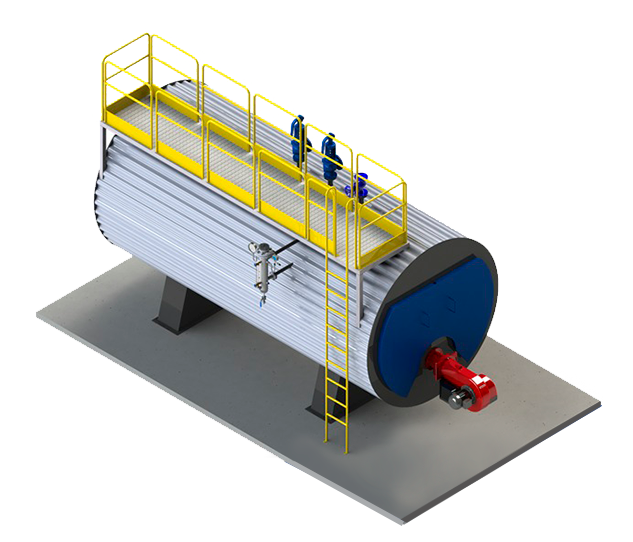

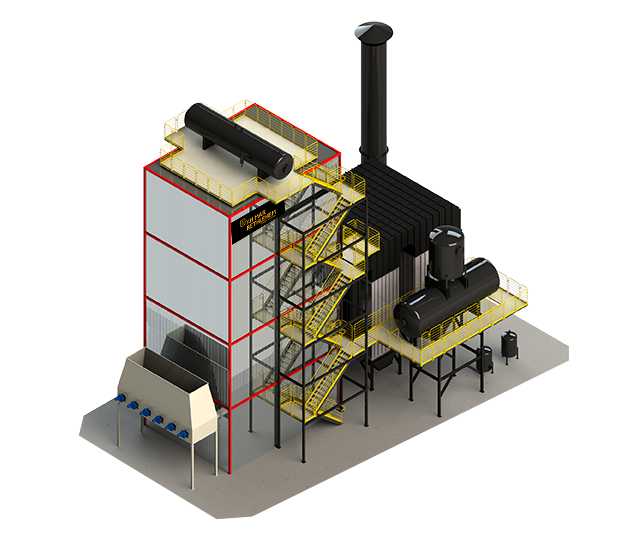

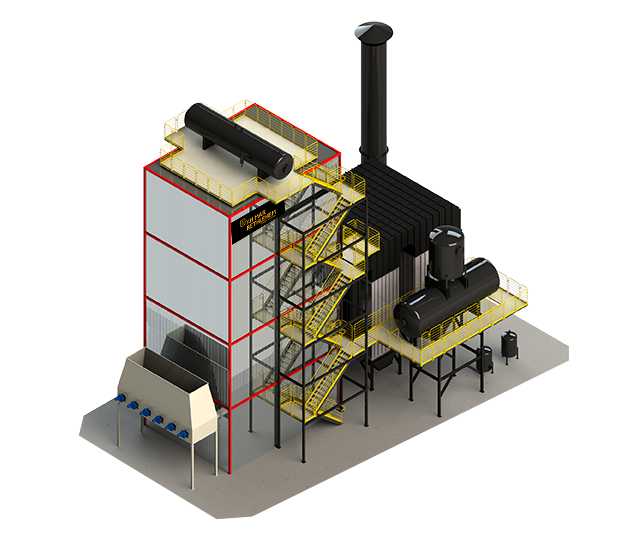

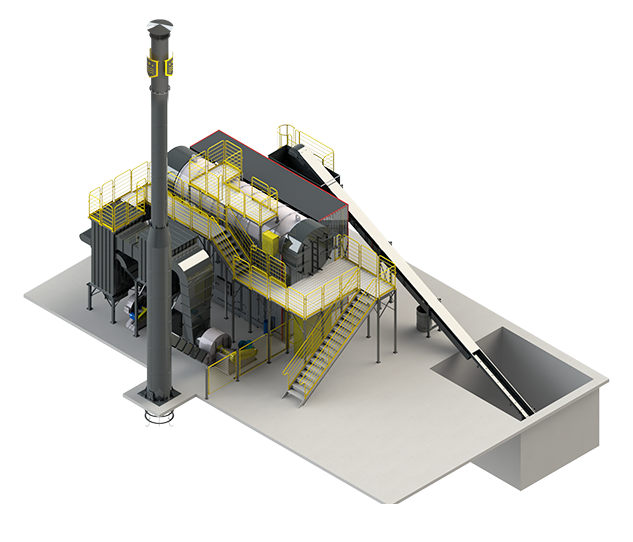

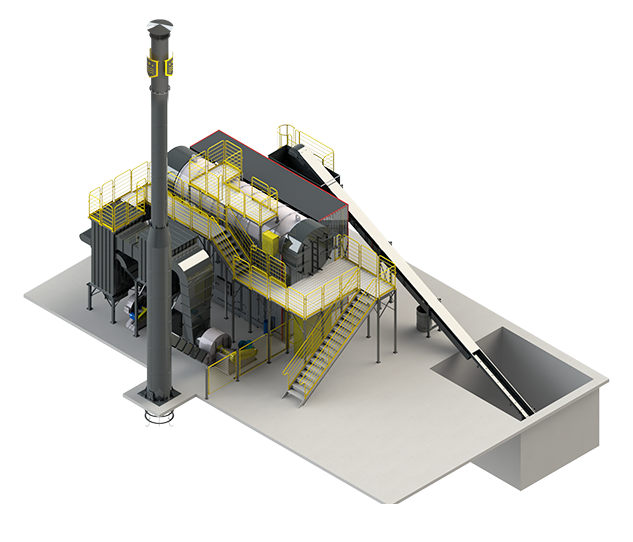

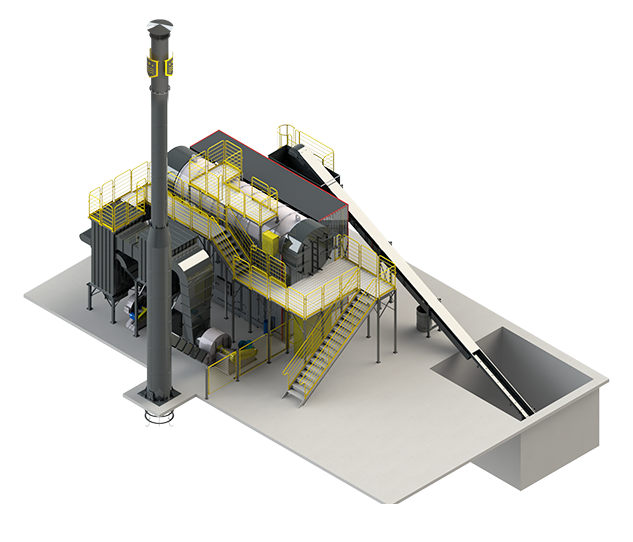

WATER TUBE BOILER

In this type of boiler, the water that will be transformed into steam passes inside the tubes and the combustion of the gases takes place around the tubes. Water tube boilers support high pressures and temperatures and produce large amounts of steam, offering greater production efficiency.

Due to these characteristics, this type of boiler is mainly used in energy generation. But it also offers the possibility of developing smaller projects for use in industrial processes.

It is also worth mentioning that it supports any type of fuel, including biomass.

WATER TUBE BOILER

In this type of boiler, the water that will be transformed into steam passes inside the tubes and the combustion of the gases takes place around the tubes. Water tube boilers support high pressures and temperatures and produce large amounts of steam, offering greater production efficiency.

Due to these characteristics, this type of boiler is mainly used in energy generation. But it also offers the possibility of developing smaller projects for use in industrial processes.

It is also worth mentioning that it supports any type of fuel, including biomass.

CALDEIRA AQUATUBULAR

Nesse tipo de caldeira, a água que será transformada em vapor passa dentro das tubulações e a combustão dos gases ocorre em torno dos tubos. As caldeiras aquatubulares, suportam altas pressões e temperaturas e produzem grande quantidade de vapor, oferecendo maior eficiência na produção.

Devido a essas características, esse tipo de caldeira é utilizado principalmente na geração de energia. Mas oferece a possibilidade de desenvolver projetos menores para utilização em processos industriais.

Ainda, vale ressaltar que ela suporta qualquer tipo de combustível, inclusive biomassa.

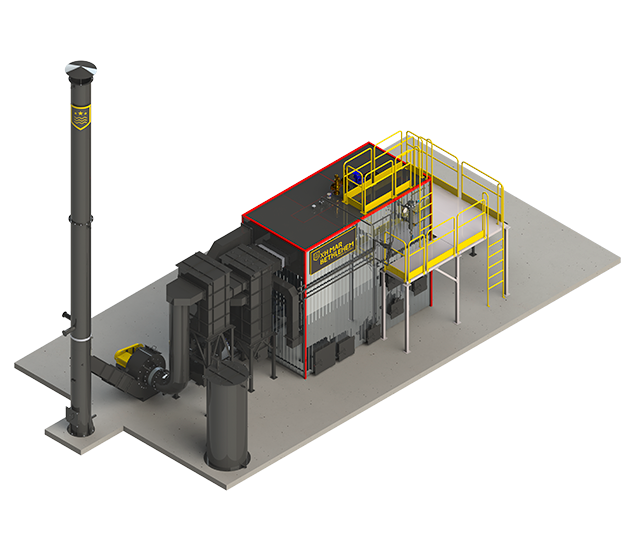

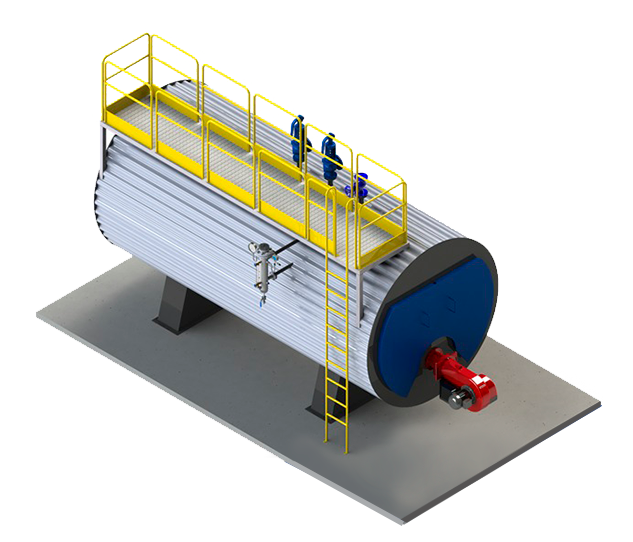

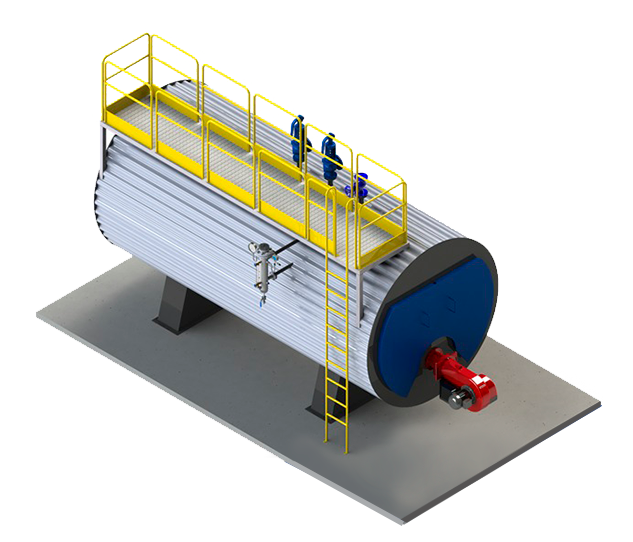

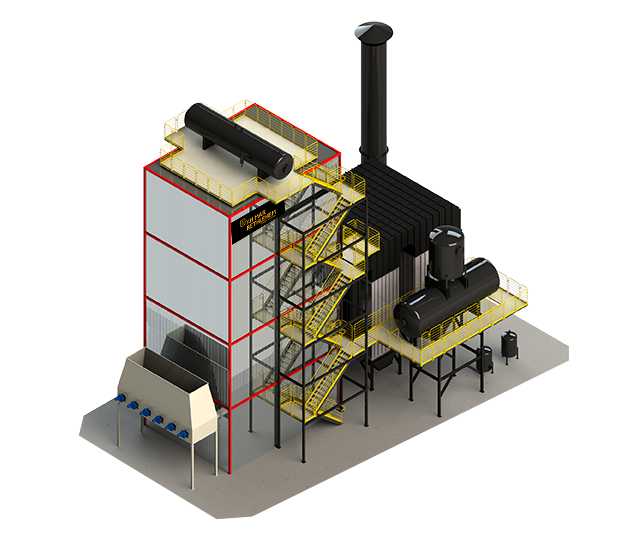

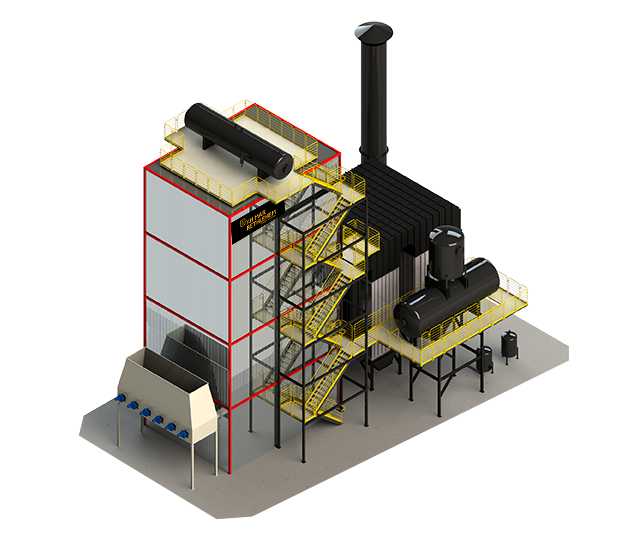

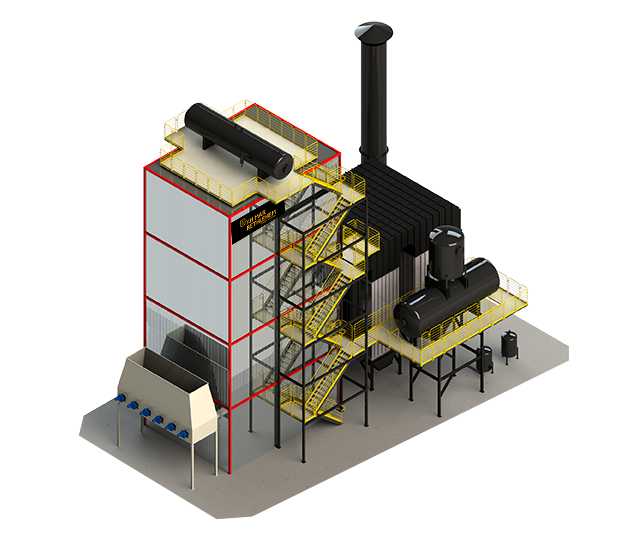

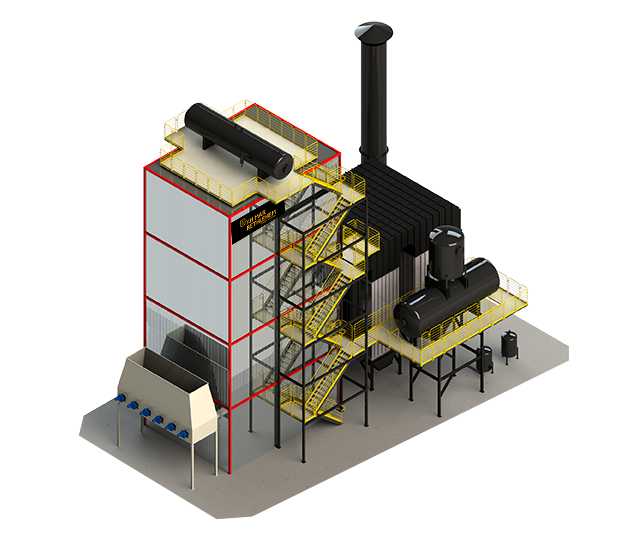

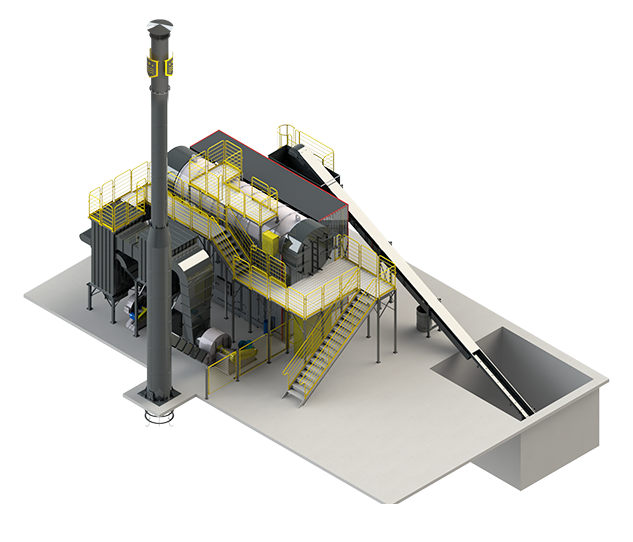

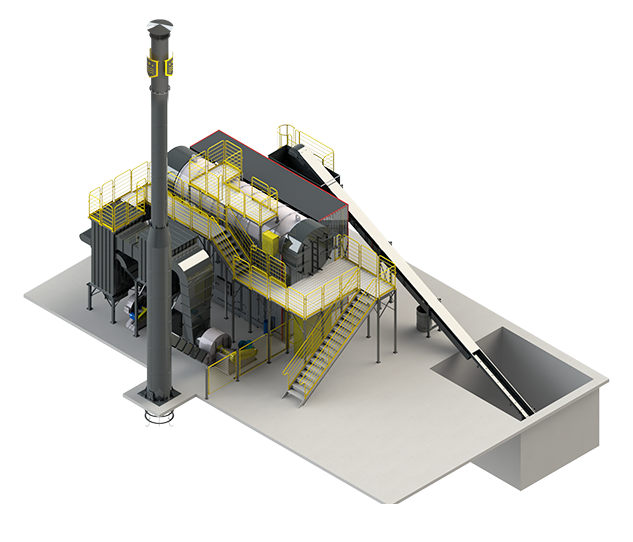

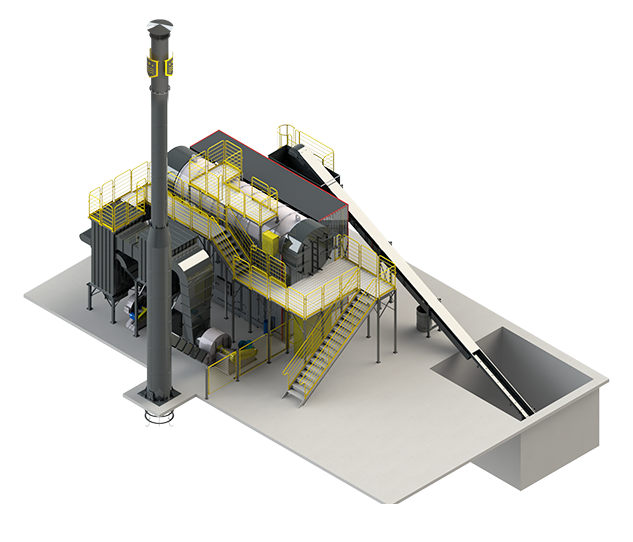

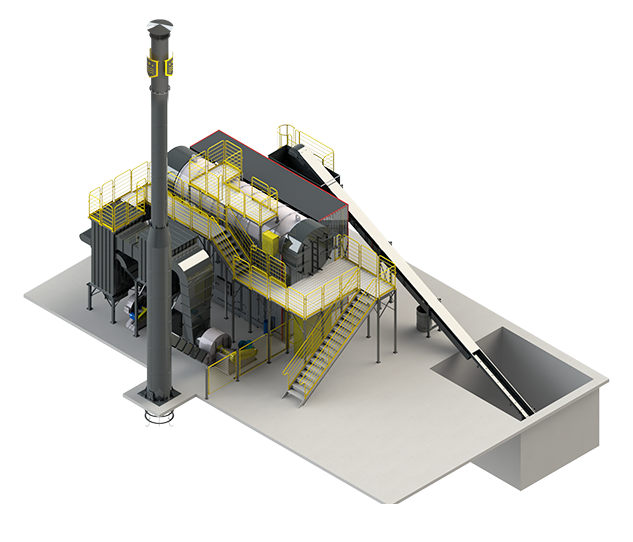

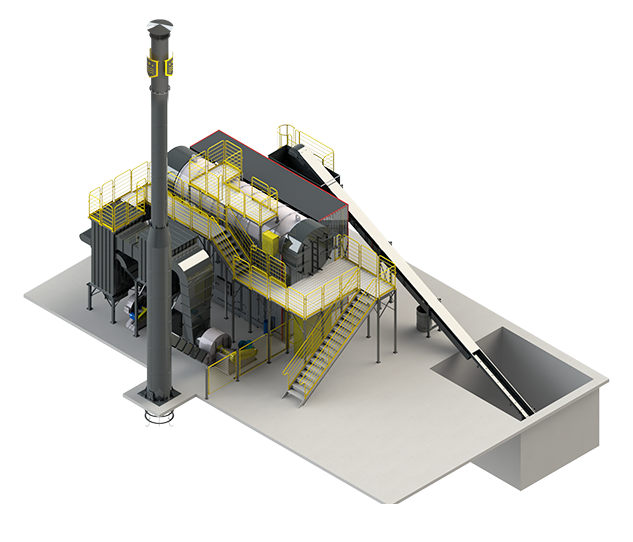

HYBRID BOILER

Hybrid boilers are a combination of water tube and flame tube boilers. They mix the combustion process of the fire tube boilers with the water tube walls, characteristic of the water tube boilers.

Steam generation with this type of boiler is carried out through the use of solid fuels.

Another characteristic worth considering when choosing this type of boiler is that it supports low pressures and temperatures.

CALDEIRA MISTA

As caldeiras mistas, são uma junção das aquatubulares e das flamotubulares. Elas misturam o processo de combustão das caldeiras flamotubulares com as paredes de tubos de água, característica das caldeiras aquatubulares.

A geração de vapor com esse tipo de caldeira é realizada através do uso de combustíveis sólidos.

Outra característica que vale se atentar ao escolher esse tipo de caldeira, é que a mesma suporta baixas pressões e temperaturas.

HYBRID BOILER

Hybrid boilers are a combination of water tube and flame tube boilers. They mix the combustion process of the fire tube boilers with the water tube walls, characteristic of the water tube boilers.

Steam generation with this type of boiler is carried out through the use of solid fuels.

Another characteristic worth considering when choosing this type of boiler is that it supports low pressures and temperatures.

DOWNLOAD OUR CATALOGUE

Check out more about our Boilers.

DOWNLOAD OUR CATALOGUE

Check out more about our Boilers

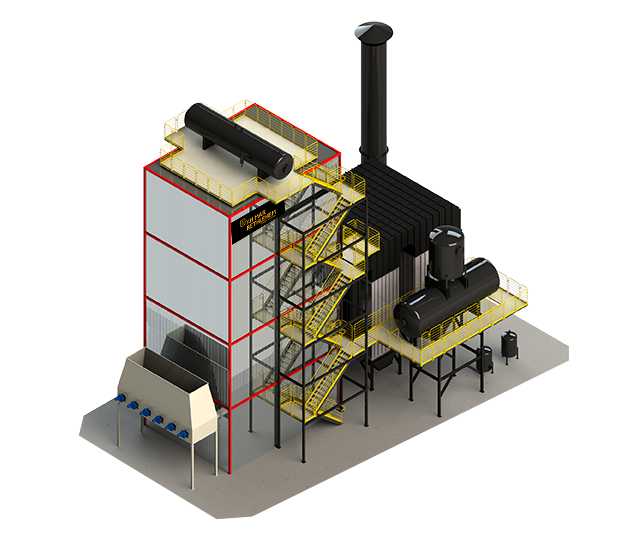

CAPACITY

From 100 kg/h up to 50.000 kg/h.

PRESSURE

From 4,0 kgf/cm² to 65,0 kgf/cm².

TEMPERATURES

140°C to 520°C.

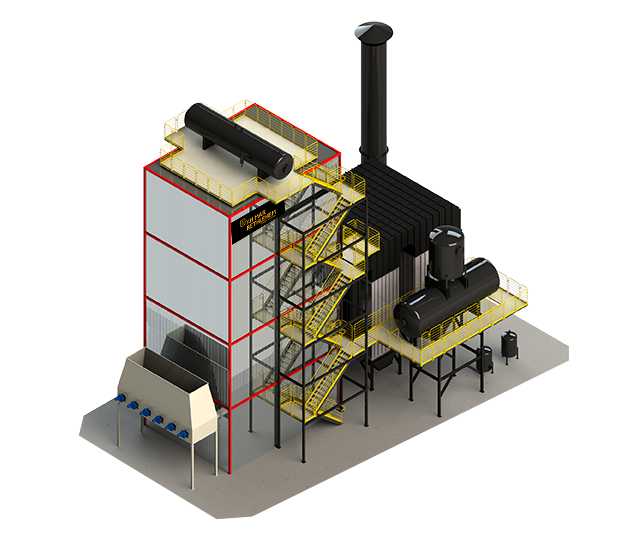

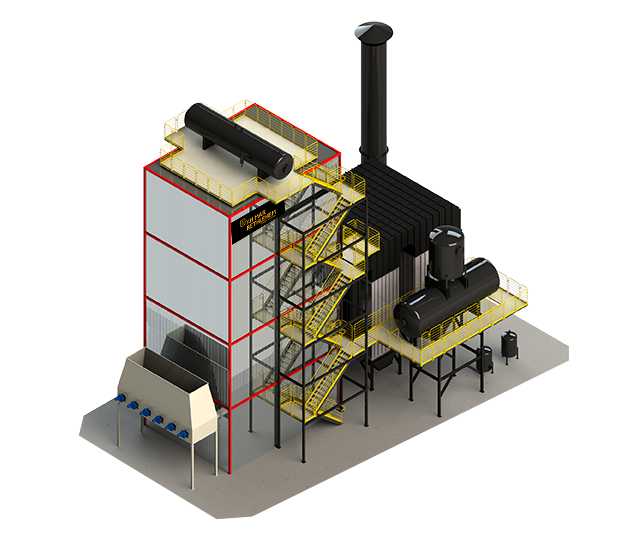

XH MAR GRATES

The XH MAR BETHLEHEM boilers have ‒ besides the fixed and movable grates, already known in the market ‒, their own designs and technologies: the Cota Zero and Drilled grates, which have low operating costs and no wear of moving parts, respectively.

COTA ZERO

DRILLED

GRELHAS XH MAR

As caldeiras da XH MAR BETHLEHEM possuem além das grelhas fixa e móvel, já conhecidas no mercado, seus próprios desenvolvimentos e tecnologias: as grelhas Cota Zero e Drilled, que apresentam baixo custo operacional e sem desgaste das partes móveis, respectivamente.

COTA ZERO

DRILLED

XH MAR GRATES

The XH MAR BETHLEHEM boilers have ‒ besides the fixed and movable grates, already known in the market ‒, their own designs and technologies: the Cota Zero and Drilled grates, which have low operating costs and no wear of moving parts, respectively.

COTA ZERO

DRILLED

STRENGTHS OF OUR BOILERS

New technologies for grates, models Cota Zero and Drilled

High thermal efficiency

Low operating cost for the Cota Zero model

No wear of moving parts in the Drilled model

Spiral steam pipe, increasing heat transfer

The air preheater is completely counterflow

Automation of 72 hours, dismissing the presence of operators on weekends

Fuel burn with high water content and varied granulometry

Low cost for the construction, since a ditch is not necessary

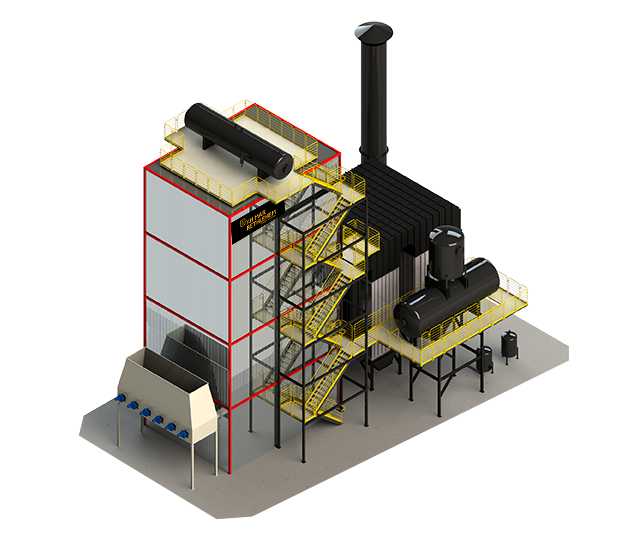

MAIN APPLICATIONS

- Indirect drying of various products.

- Co-generation and electricity generation plants up to 10.0 MW.

- Supply of saturated steam for the beneficiation of products in the most diversified sectors of industry.

FUELS

- SUGARCANE BAGASSE

- BRIQUETTE

- NAPIER GRASS

- COAL

- RICE HULLS

- WOODCHIP

- GAS (NATURAL AND LPG)

- FIREWOOD

- INDUSTRIAL SLUDGE

- WOOD SHAVING

- COAL COKE BREEZE

- OILS

- PELLETS

- FOREST RESIDUES

- SAWDUST

- OTHER FUELS ON REQUEST

MAIN APPLICATIONS

- Indirect drying of various products.

- Co-generation and electricity generation plants up to 10.0 MW.

- Supply of saturated steam for the beneficiation of products in the most diversified sectors of industry.

FUELS

- SUGARCANE BAGASSE

- BRIQUETTE

- NAPIER GRASS

- COAL

- RICE HULLS

- WOODCHIP

- GAS (NATURAL AND LPG)

- FIREWOOD

- INDUSTRIAL SLUDGE

- WOOD SHAVING

- COAL COKE BREEZE

- OILS

- PELLETS

- FOREST RESIDUES

- SAWDUST

- OTHER FUELS ON REQUEST

REQUEST A QUOTE

Our staff is ready to assist you

REQUEST A QUOTE

Our staff is ready to assist you

ADRESS

Highway SC 350 | N° 4851 | Downtown | CEP: 89170-000 | Laurentino/SC | Brazil

CONTACT

+55 (47) 3546-1344

comercial@xhmarbethlehem.com.br

OFFICE HOURS

Monday to Friday

8:00 a.m. to 11:30 a.m.

1:30 p.m. to 5:30 p.m.

ADRESS

Highway SC 350 | N° 4851 | Downtown | CEP: 89170-000 | Laurentino/SC | Brazil

CONTACT

+55 (47) 3546-1344

comercial@xhmarbethlehem.com.br

OFFICE HOURS

Monday to Friday

8:00 a.m. to 11:30 a.m.

1:30 p.m. to 5:30 p.m.